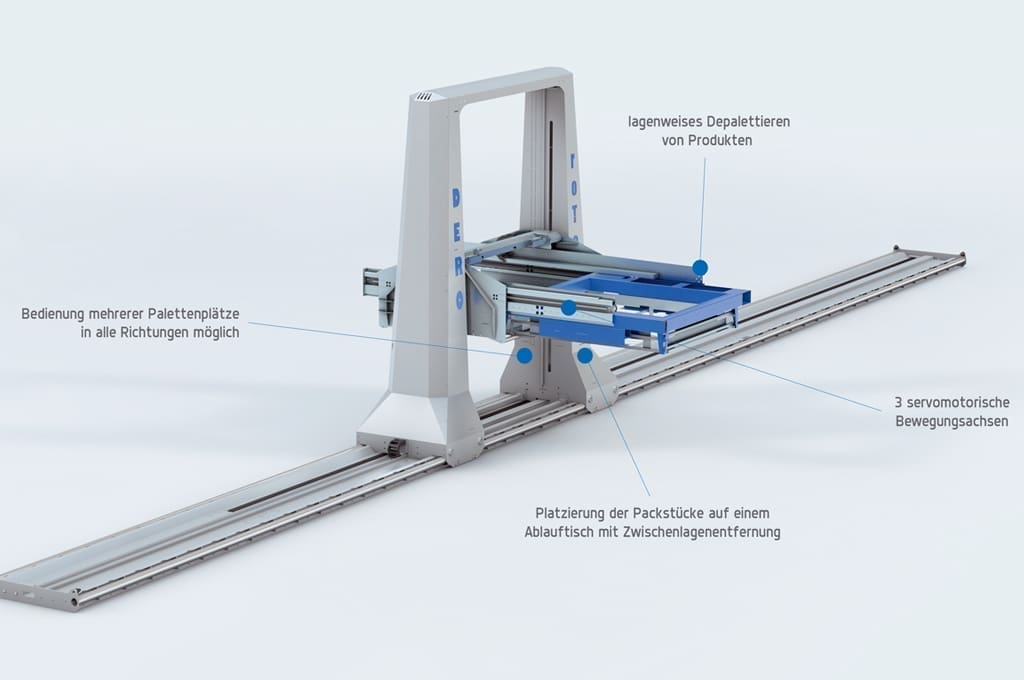

3 axis principle:

With its three axis of motion the robot positions the package layer safely on a discharge table and removes the interlayers at the same time. The roTeg depalletizing robot II works with a gripper which first encloses the upper package layer and centers it with clamping jaws. The whole layer is pulled over an integrated cover plate. The layer is pushed back on the discharge table. The robot takes the existing interlayers with a suction system and puts them in a separate magazine.

Always on the move: The roTeg depalletizing robot II for depalletizing any number of pallet spaces.

The roTeg depalletizing robot II is designed for clearing of packaged items such as glasses, cans or bottles in layers in the pharmaceutical and food industries and is characterized by its flexibility and reliability. It is useful for different package diameters and can serve several pallet spaces.

For variable package diameters:

The roTeg depallatizing robot II can even depallatize different package diameters without any problems due to the centering frame of the grippping system which encloses the entire layer. Because the fixiation works without external pressure the material is handled very gently.

Low maintenance and robust construction:

When developing the system the use of low maintenance components were one of the major important points. This is why the three axis are driven by maintenance free servomotors. The stable and simple kinematic ensures minmal maintenenace costs.