Your selection for gripping technology for palletizing robots

The performance of the robot system can be especially influenced by choosing the right gripper.

Usually the single gripper is the right choice for small outputs and bulky packages. Multiple grippers that can handle two or more packages at the same time are better suited for palletizing capacities of more than 500 packages per hour.

Multifunctional grippers are used when in addition to the actual pick and place tasks, additional functions such as interlayer removal or measurement and testing processes are to be integrated.

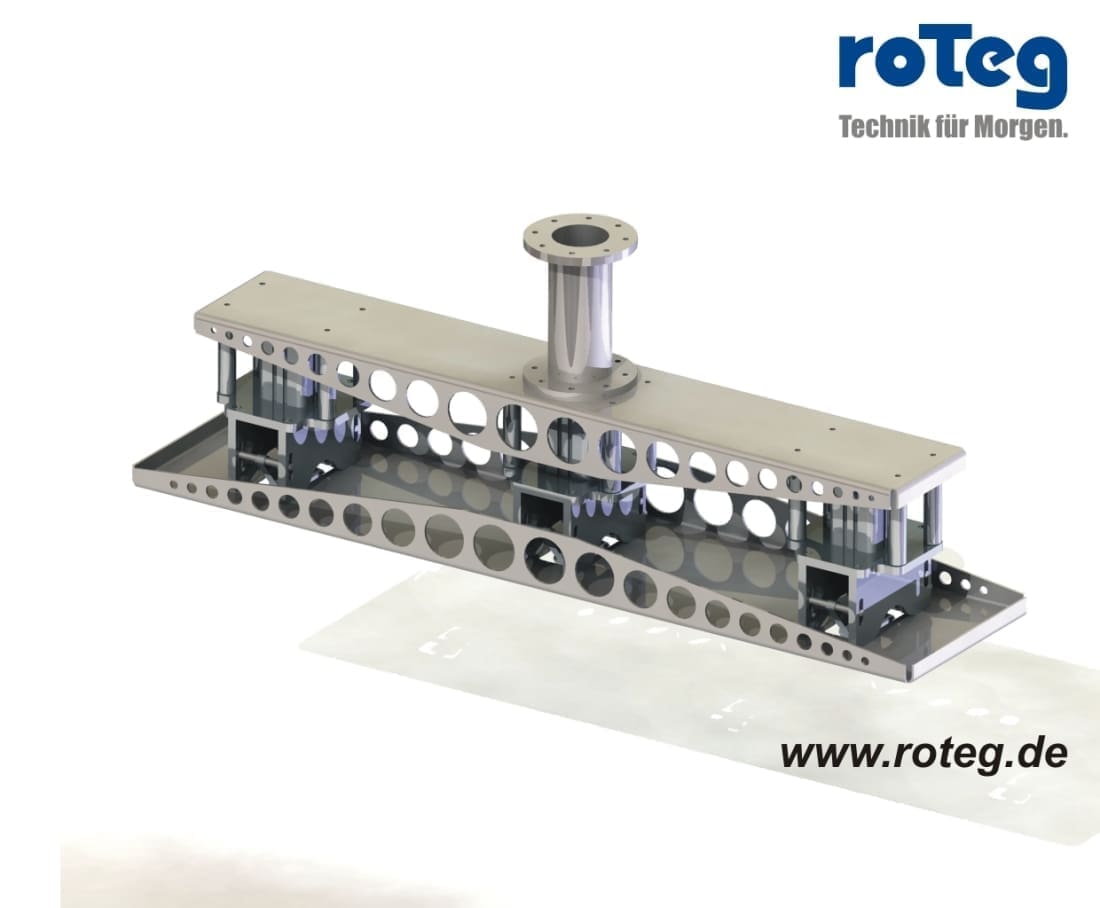

Take a look at the following pages to see some examples of the different gripping systems.

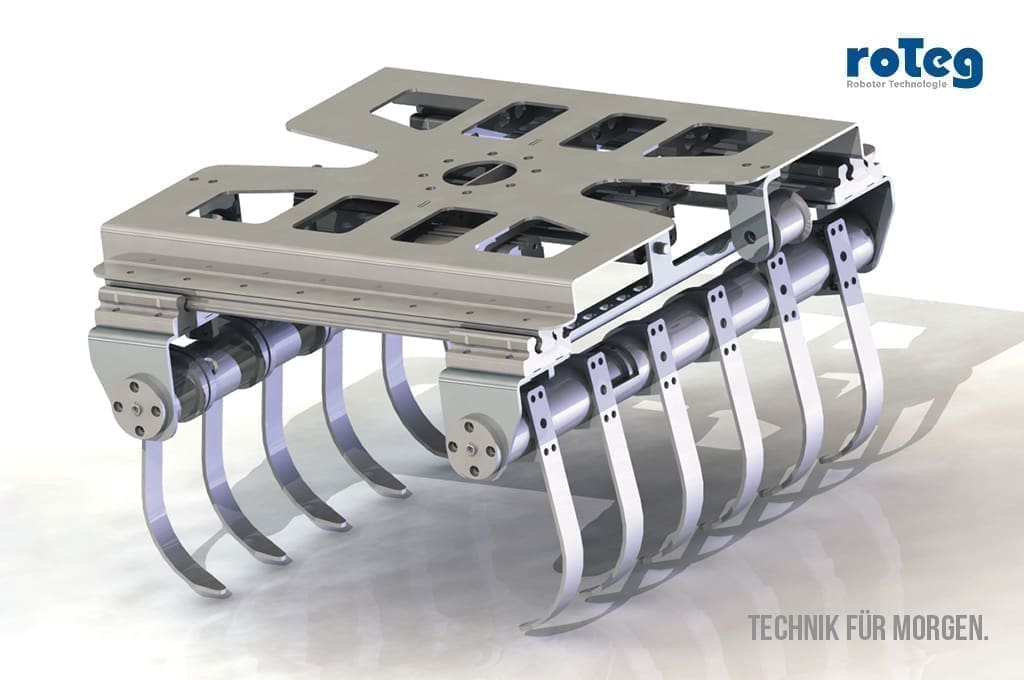

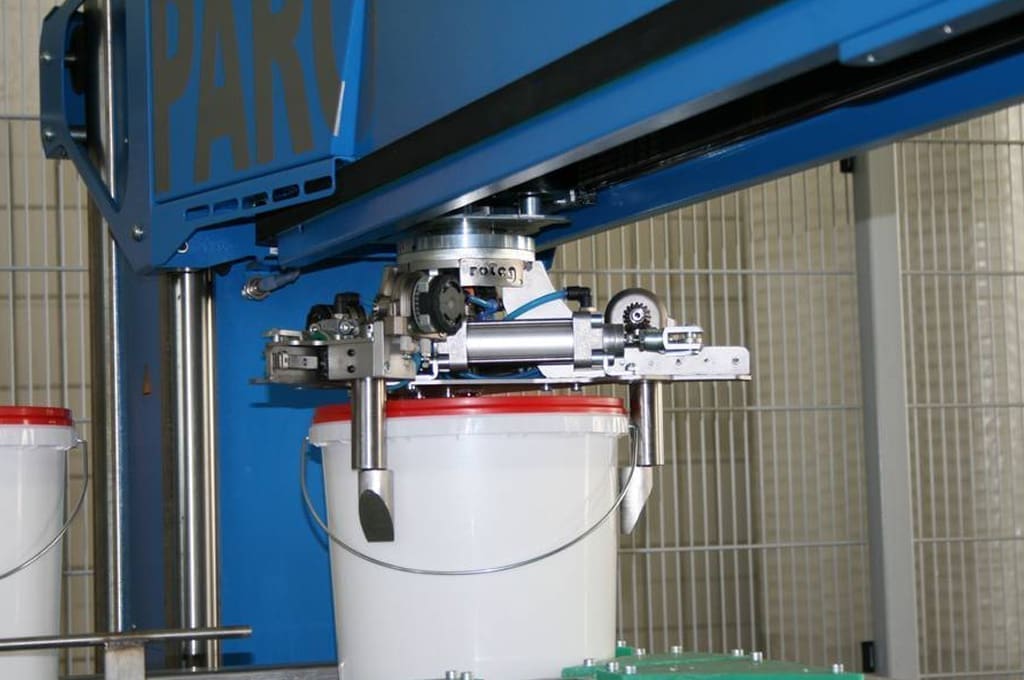

The above illustration shows a palletizing robot with a special gripper for Hobbocks. You can find further examples of single or special grippers for palletizing robots [here].

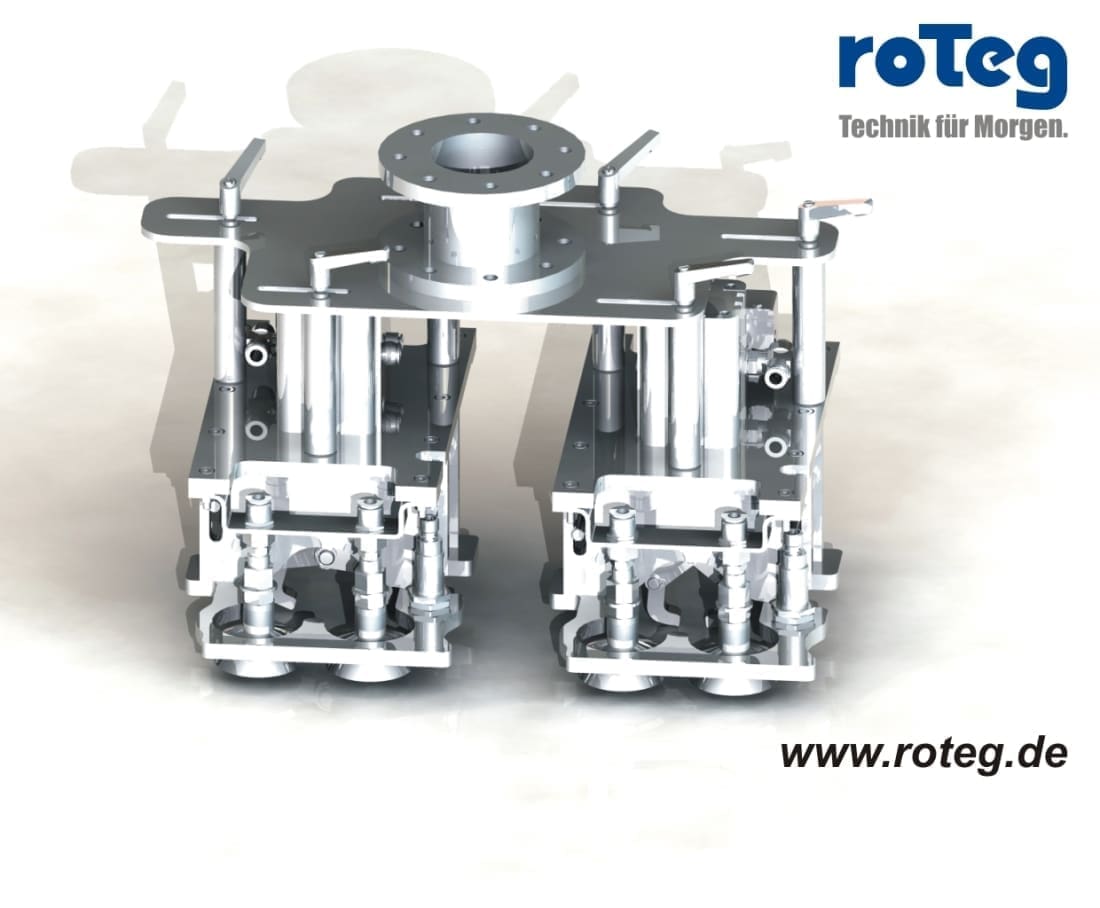

The above illustration shows a palletizing robot with a double gripper for cardboard boxes. You can find further examples of multiple grippers for palletizing robots [here].

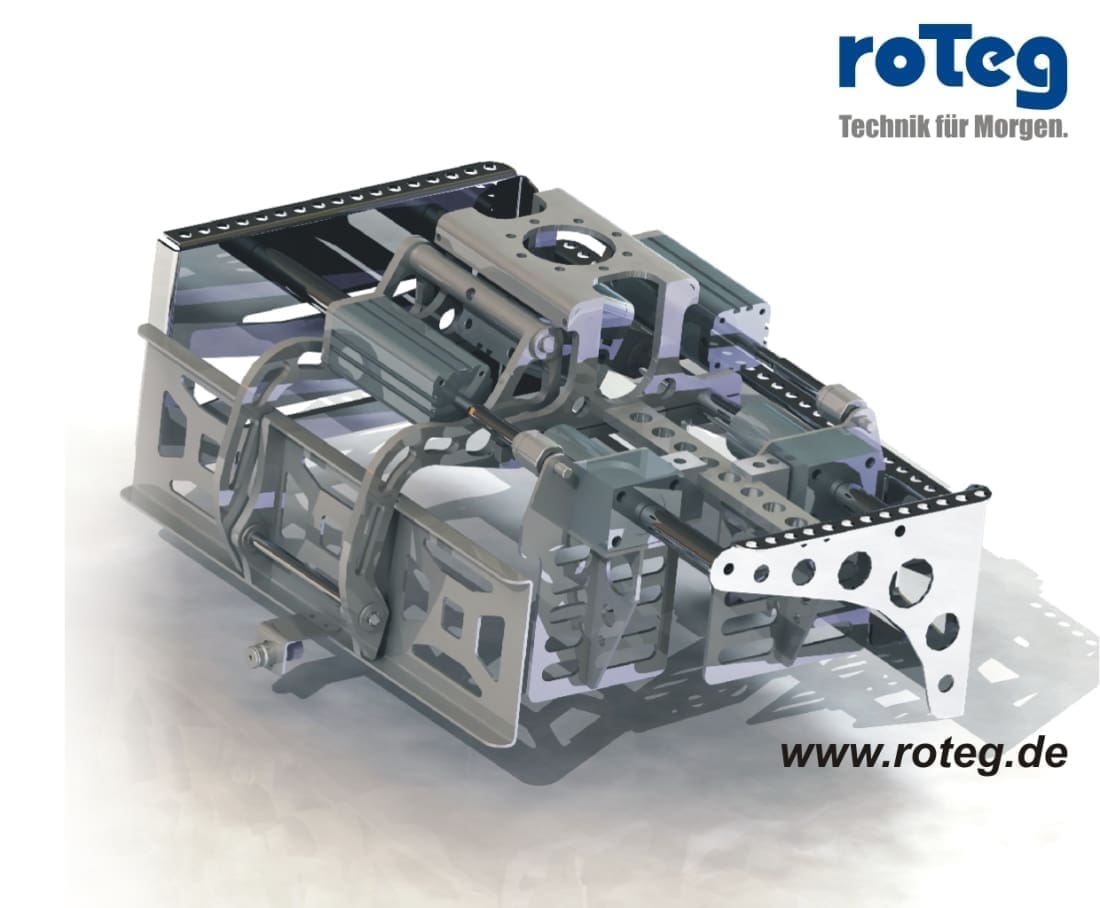

The above illustration shows a layer by layer palletizing with tray support. You can find further examples of multifunctional grippers for palletizing robots [here].