Pallet conveyor technology

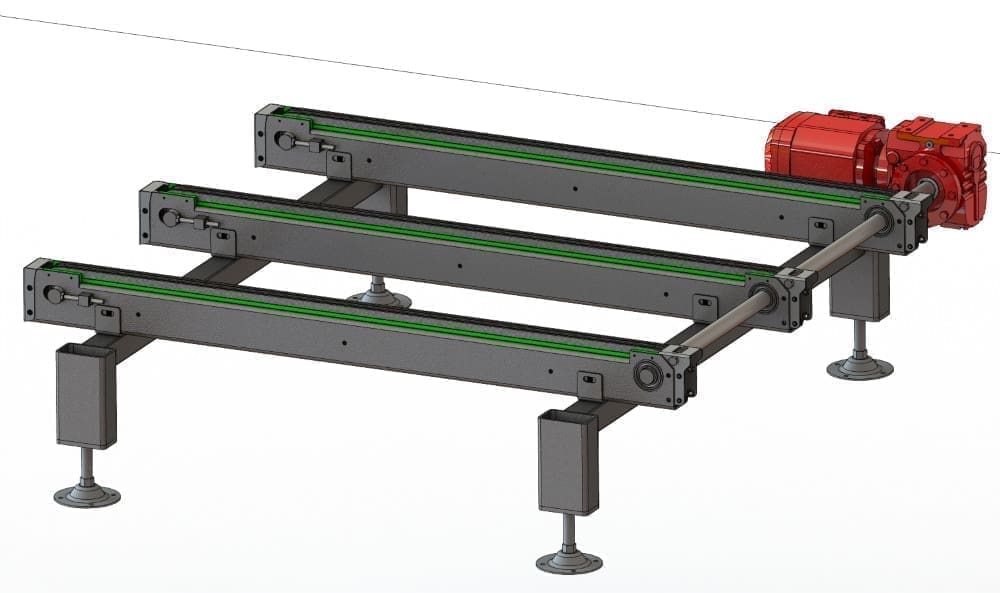

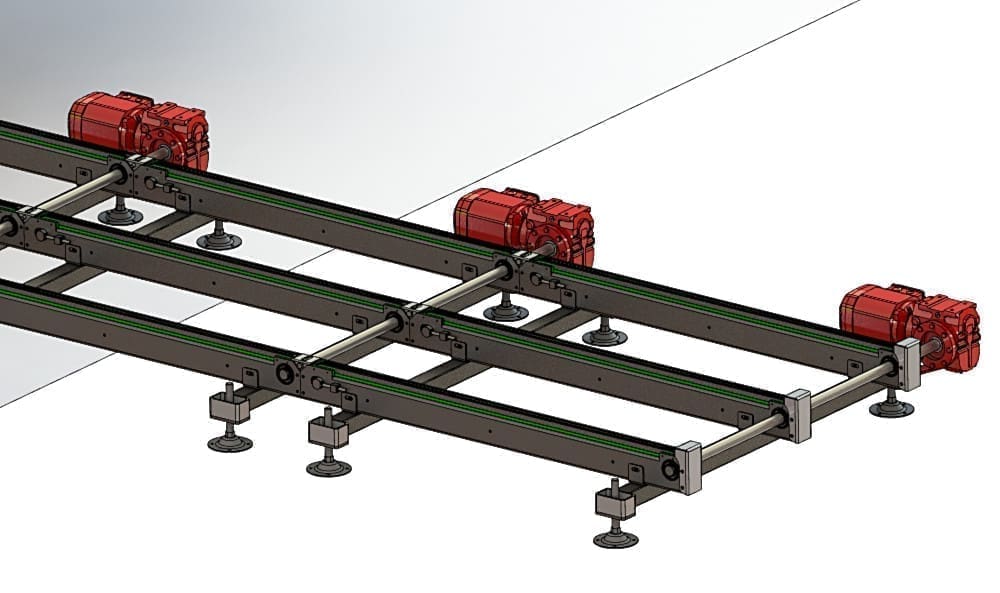

Product features chain conveyor

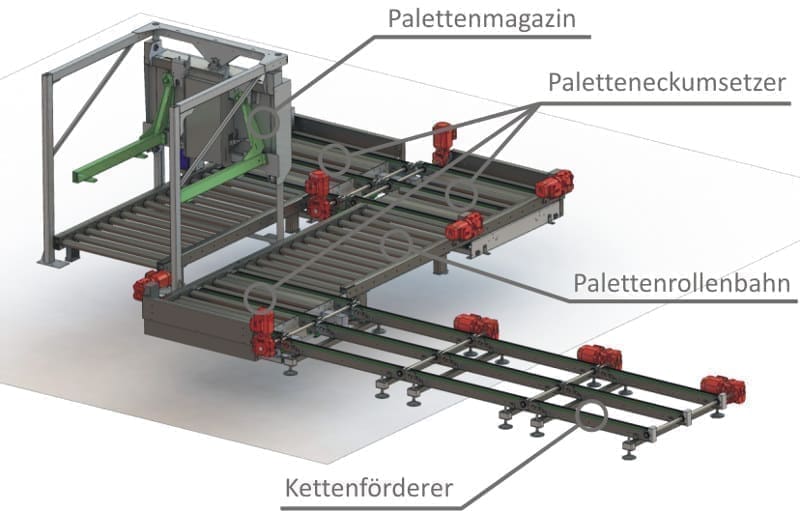

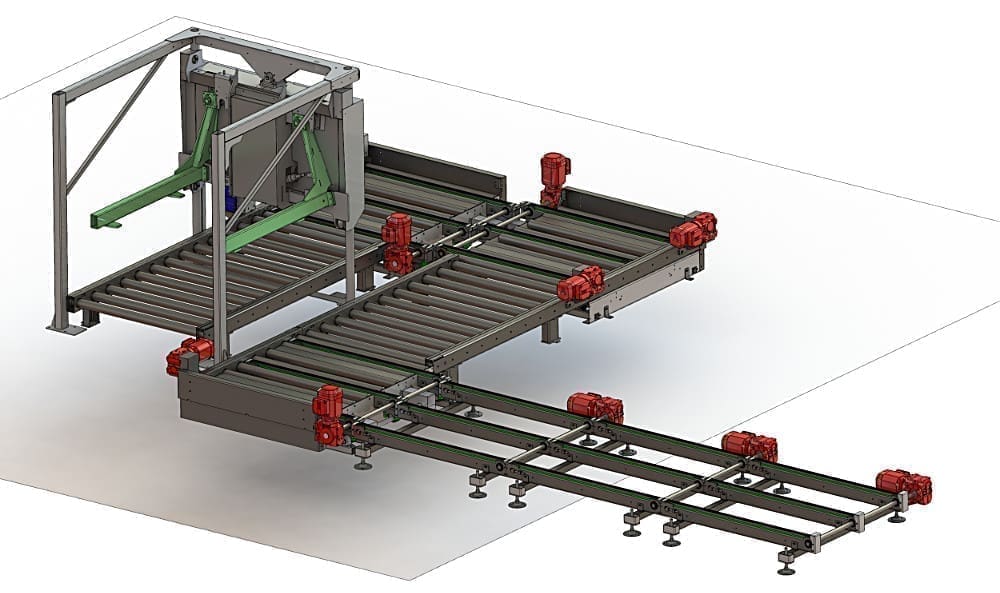

The corner transfer is used for the cross transport of pallets. The side guides of the offered pallet conveyor technology are made of galvanized steel such as the level adjustable feet.

The conveyor technology is designed for a transport speed of 0,2 m/second and is driven by a three phase asynchronus motor from the company SEW.

Usage

The use of pallet magazines and conveyor technology for pallets achieves a higer degree of automation and increases the production performance. The delay free exchange of full against empty pallets is crucial for the palletizing performance of the robot.

As soon as there are multiple pallets in the gripping area this must also be taken into account when considering the achievable palletizing performance.

Application advantages

Features

Application example in the palletizing system

Chain conveyor

SummaryUse for production

The corner transfer is used for the transverse transport of pallets. The side guides of the ordered pallet conveyor technology is made of galvanized steel such as the level regulating feet.

The pallets are transported lengtways on rollers, in the transverse direction chains are used for the transport.