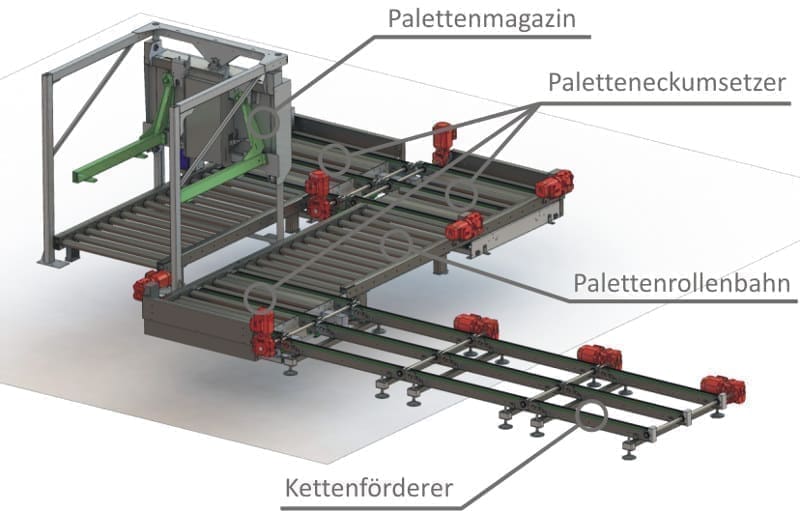

Pallet conveyor technology

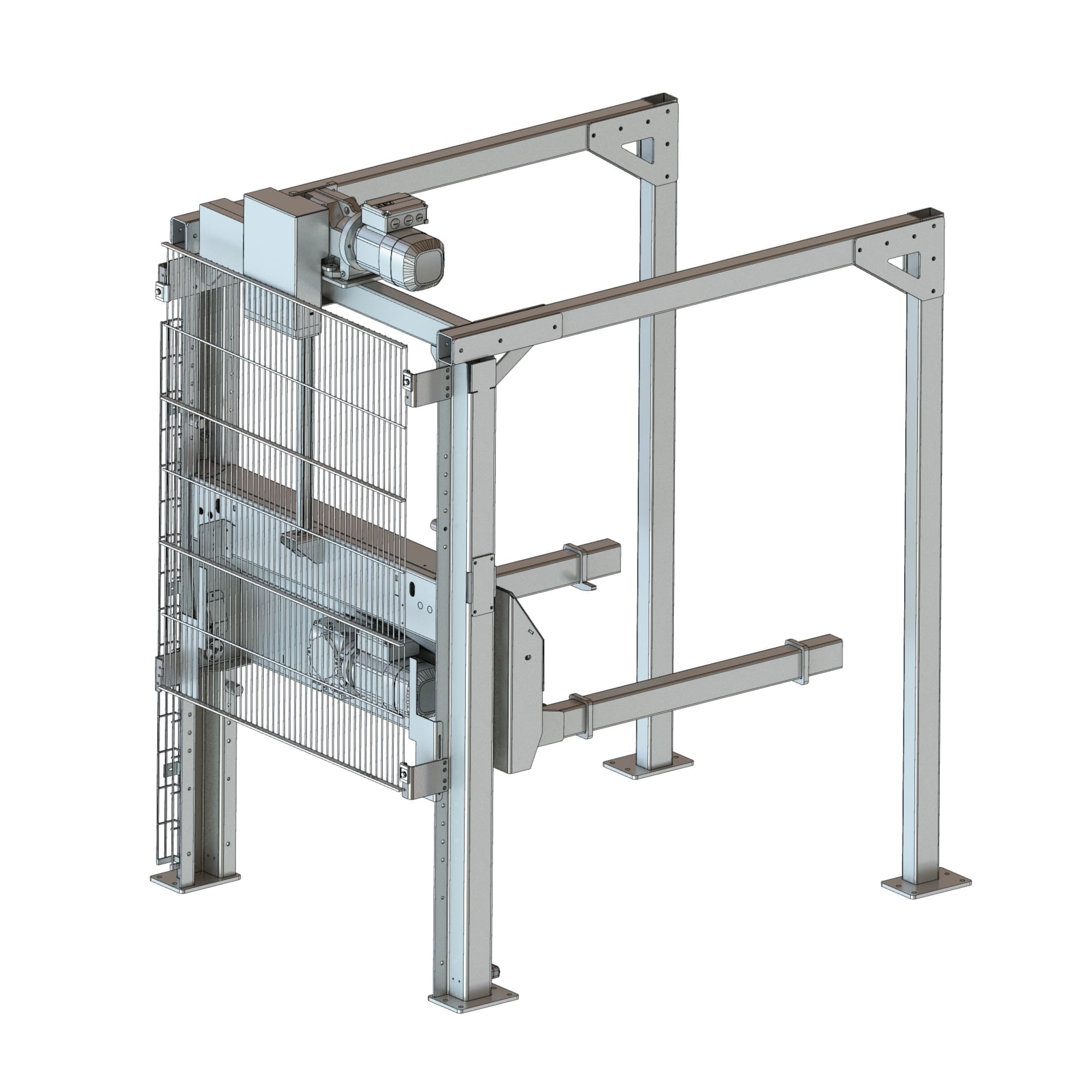

Product features empty pallet magazine

The pallet magazine is designed to save up to 15 pallets in the stack. From the empty pallet magazine, pallets can be individually and automatically transmitted to the downstream conveyor system for supplying empty pallets to the robot system.

It is a robust, galvanized steel construction. The magazine is integrated into the central control of the robot system.

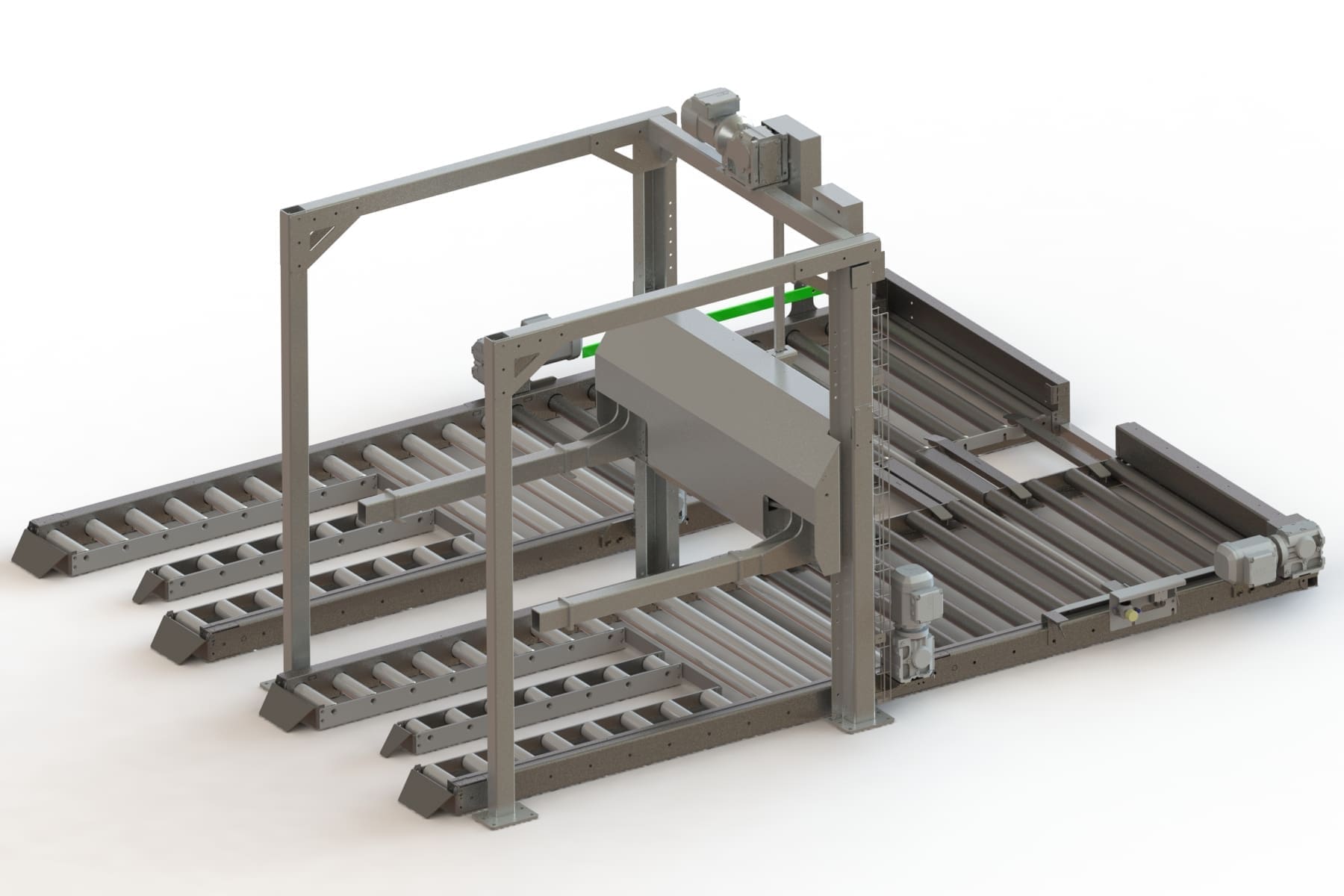

Usage

By using pallet magazines, a pallet can be transported to the palletizing station without negatively affecting the performance of the palletizing robot. The degree of automation will be raised and the production performance increased. The robot automatically retrieves the required empty pallets from the empty pallet magazine.

The instant exchange of full against empty pallets is crucial for the palletizing performance of the robot.

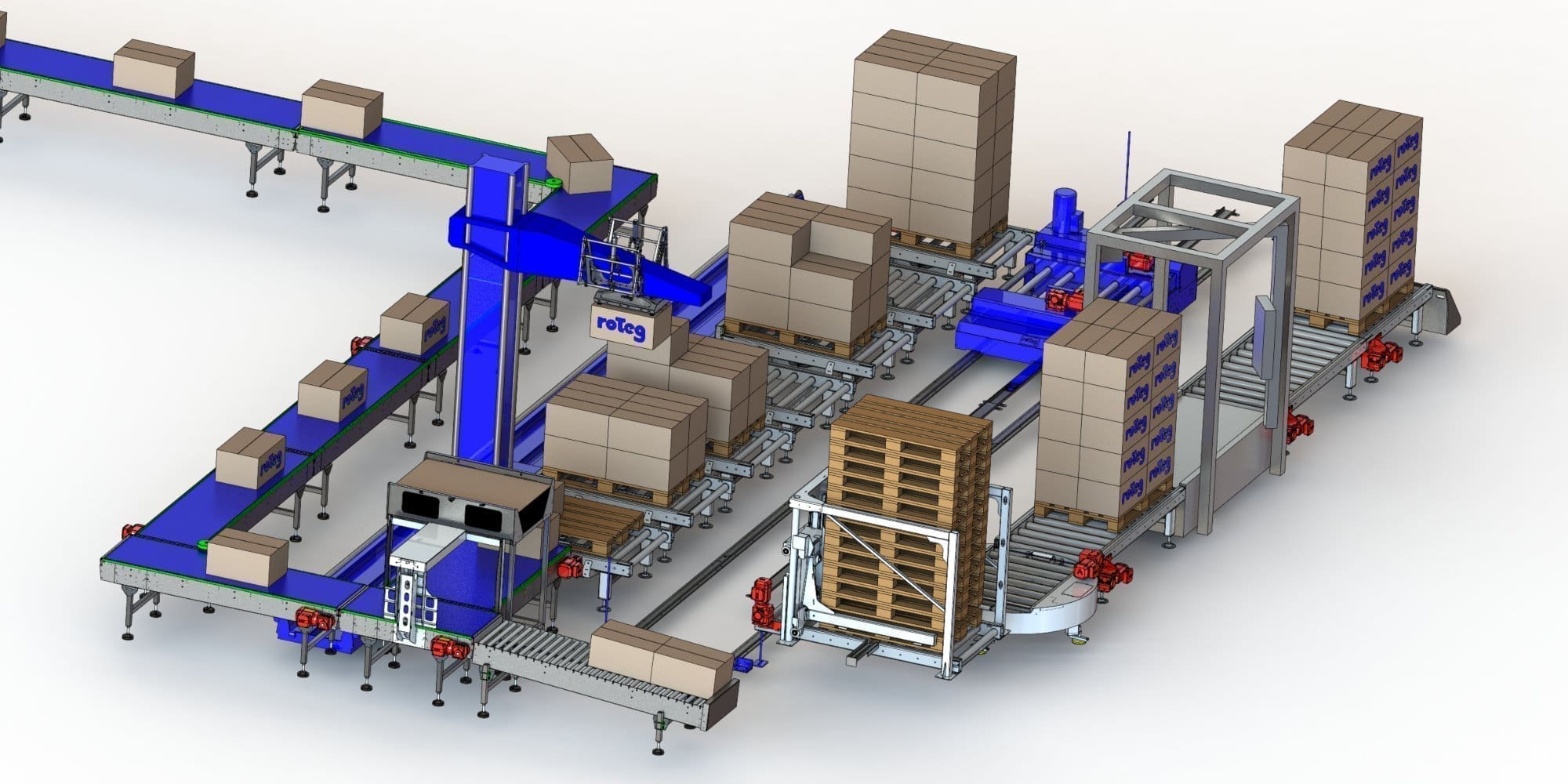

Application advantages

Features

Application examples in the palletizing system

Pallet magazine

SummaryUse for production

The empty pallet magazine saves up to 15 empty pallets with euro or industrial pallet size. The format is adapted automatically.

The palletizing performance is increased by increasing the degree of automation.