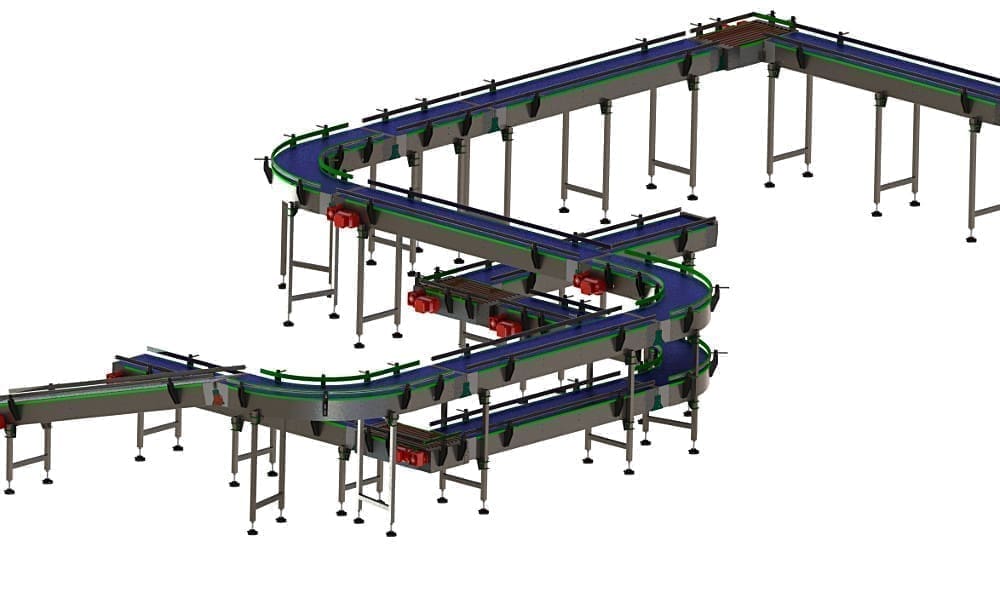

Package conveyor technology

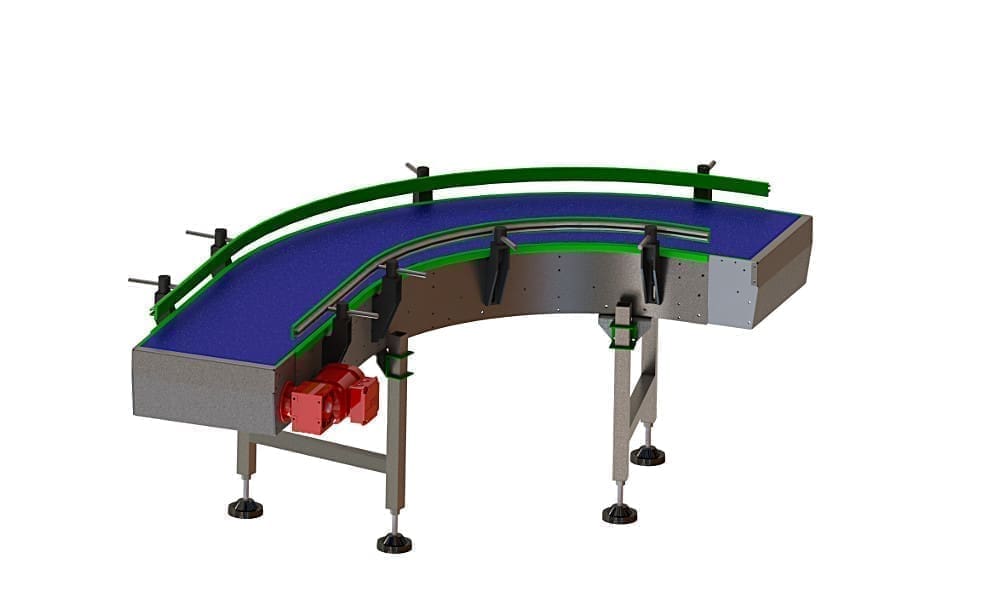

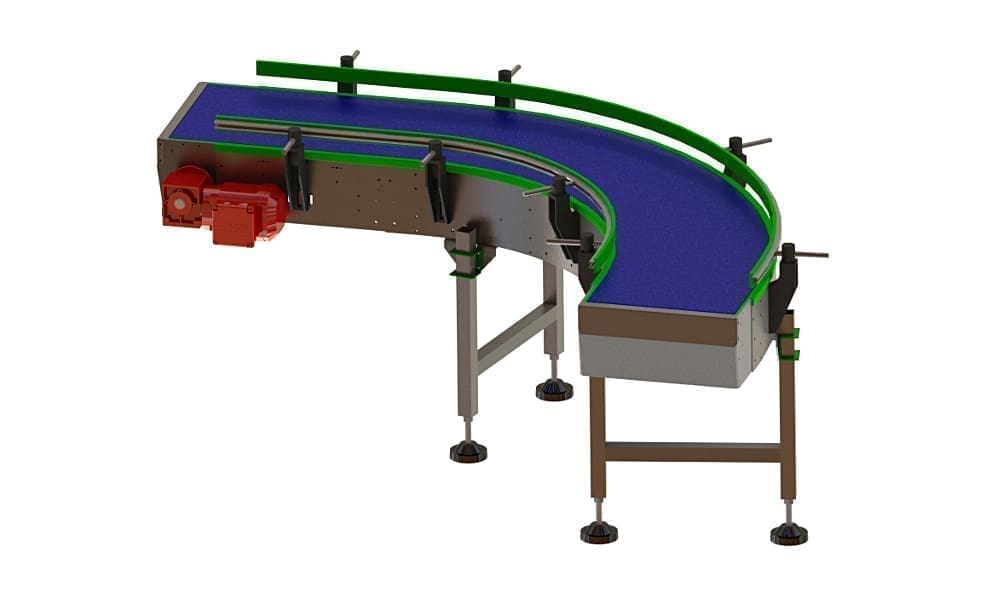

Product features mat segment curve

The conveyor technology for packages takes over the packages of the robot cell and leads them to a transfer station in the robot cell.

The side guides of the offered conveyor technology are made of galvanized steel as well as the level adjustable feet.

The modular conveyor technology is designed for a transport speed of 0,2 – 0,8 m/second and is driven by three phase asynchronus motors from SEW.

Usage

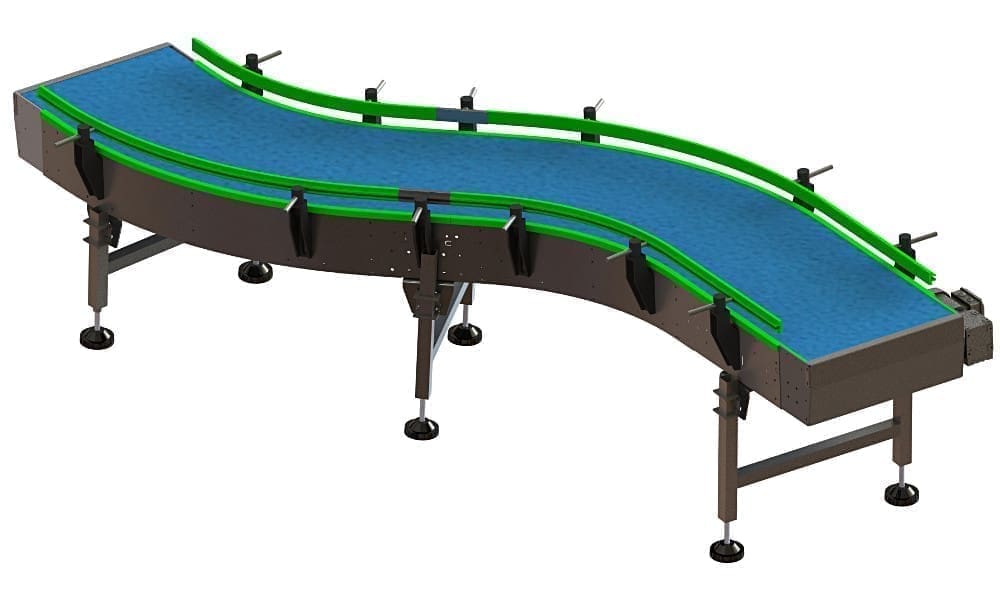

The conveyor technology is used as a mat segment for the curved transport of the packages.

It is possible to combine several segments to extend the transport route and the curved angle.

Application advantages

Features

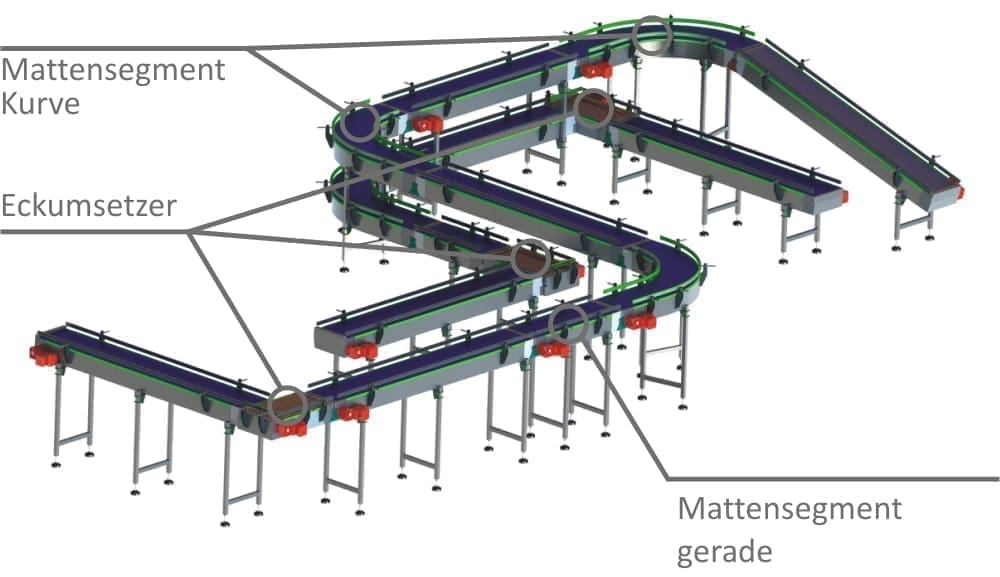

Application example in palletizing system

Mat chains

SummaryUse for production

The mat segments are used to transport the packages in a straight line.

The combination of more segments to extend the transport route is possible such as the use of a segment as an end piece in combination with a centering.